As industries continue to adopt advanced electrical and electronic systems, the need for reliable cable protection and insulation has become more important than ever. Heat shrink tubing has emerged as one of the most versatile and dependable solutions for safeguarding wires, cables, and electrical components. From moisture sealing to abrasion resistance, its wide range of benefits makes it essential in electrical, industrial, automotive, and telecom environments. This article explores the top advantages of heat shrink tubing and why it remains indispensable across modern applications.

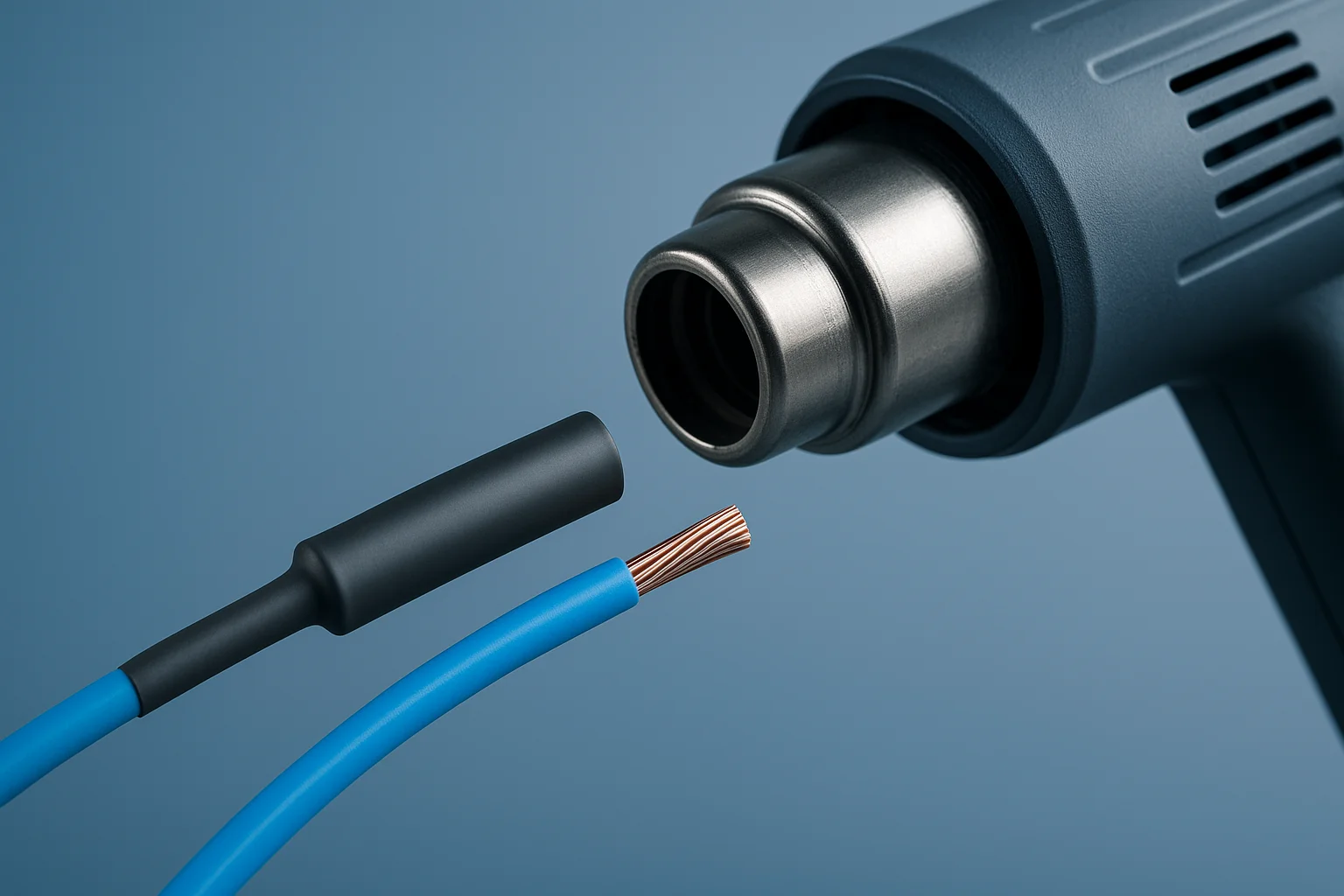

Heat shrink tubing is a specially engineered plastic tube designed to shrink tightly around wires or components when heat is applied. Once shrunk, it forms a strong, secure, and protective layer that enhances safety, performance, and durability. Used worldwide in electrical and industrial systems, heat shrink tubing is available in materials such as polyolefin, PVC, fluoropolymer, silicone, and elastomers.

Heat shrink tubing provides reliable electrical insulation, making it essential for preventing short circuits and electrical failures. Its high dielectric strength ensures safety and stability, even in demanding low- and high-voltage environments. This makes it ideal for everything from basic wiring repairs to complex electrical assemblies.

One of the major benefits of heat shrink tubing is its ability to shield cables from environmental factors such as:

Moisture

Dust

Chemicals

Oil

UV exposure

By preventing corrosion and oxidation, it significantly enhances the lifespan of cables used in harsh indoor and outdoor conditions.

Heat shrink tubing reinforces weak points such as cable joints, connectors, and splices. It helps absorb stress caused by bending, vibration, or constant movement, reducing the risk of wire breakage or insulation failure.

In industries where cables are exposed to friction or rugged surfaces, heat shrink tubing acts as a protective armor. It prevents abrasion, surface damage, and general wear, making it suitable for machinery, automation systems, and heavy-duty electrical installations.

Adhesive-lined heat shrink tubing provides excellent strain relief for connectors and joints. It reduces pull-related damage and ensures that cables remain secure even when exposed to tension or repetitive movement.

Heat shrink tubing helps organize and bundle cables neatly, making wiring systems safer and easier to maintain. With options for multiple colors and sizes, it also supports color-coded identification and enhances the overall appearance of electrical panels and cable assemblies.

Many industrial-grade heat shrink tubes are engineered to withstand extreme temperatures and voltage variations. This makes them suitable for demanding environments such as:

Power distribution systems

Heavy machinery

Automotive wiring harnesses

Aerospace and defence systems

Their durability ensures uninterrupted performance even under extreme conditions.

Heat shrink tubing is widely used across:

Electrical and power distribution

Automotive and transportation

Telecom and fiber optics

Electronics and PCB manufacturing

Aerospace and defence

Railways and heavy machinery

Its versatility makes it one of the most widely used cable insulation components in modern industries.

Heat shrink tubing offers exceptional protection, insulation, and durability, making it essential for industrial, electrical, automotive, and telecom applications. Whether it’s reinforcing cable joints, safeguarding wiring from harsh environments, or improving cable organization, its benefits are undeniable. As modern electrical systems grow more advanced, the importance of quality heat shrink tubing will only continue to rise.